In the late 1970s, diamonds were rapidly rising in value. But stones with similar characteristics, as measured by the traditional 4Cs, had quite a wide value spread. Dealers were aware of the issue, but no one in particular explained the mystery. It became apparent that to answer the question of what was creating stratification in the value of diamonds, the quality of cut had to be taken into consideration and could, in fact, be the deciding factor in establishing a stone’s market value. However, at the time, the 4Cs limited the use of the word “cut” to refer only to the outline shape of a stone. A clear definition of the term was needed.

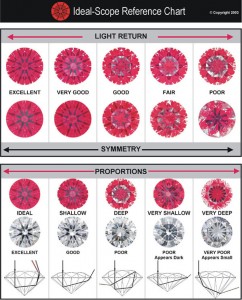

Tolkowsky and other experts had published standards for cutting a diamond. There were four categories of cut by Gemological Institute of America (GIA), 11 categories in American Gem Society’s (AGS) early cut system and the ABC system published in the Rapaport Diamond Report price sheets every month. Although these standards were supposedly different, there appeared areas of convergence on cut standards that mirrored visual observation. This was not a coincidence. Since diamond material has specific optical and durability properties, one must cut a diamond within a certain range of cut parameters to produce a durable stone. Spread-to-depth ratio must be pleasing as well for a stone to be appreciated by consumers. Crafting a diamond with a high degree of symmetry pleases the eye. Excellent surface polish represents a high level of craftsmanship and increases light return from surface reflections.

DIAMOND REPORT CARD 1985

This research led to a better understanding of “cut” that could explain differences in values of stones otherwise similar on 4Cs. By 1985, the Philadelphia-based gem appraisal company D. Atlas & Co. developed a Diamond Report Card, which reported the traditional 4Cs as well as a “Suitability for Use” rating based on a weighted scale for various cut parameters. The report card was designed to mimic an elementary school report card in appearance and had some success in the local jewelry market.

The Suitability for Use score was intended to give a definitive yet simple-to-use value that could be used to compare different stones and provide an assessment of how well a diamond was suited for use. The Report Card allowed consumers to make an informed choice.

Improvements to the Diamond Report Card were made around 1992 and incorporated in the AGA-CERT® developed by Accredited Gem Appraisers (AGA), a division of D. Atlas. In the new standard, based on research as well as years of experience, the grading of the craftsmanship of a diamond was improved and extended to any round and fancy shapes. The result was a standard that could be used by cutters, dealers, grading laboratories and consumers. James Jolliff and Joseph Tenhagen assisted in this advancement; both are current Senior Members of the National Association of Jewelry Appraisers (NAJA).

According to the new system, a diamond is assigned one of eight cut quality grades, with the very finest cut grade being “1A.” This cut standard has been evaluated by independent experts and found to be right at the center of the best cut parameter space; see the GIA Gems and Gemology article in the Fall 1998 edition, “Modeling the Appearance of the Round Brilliant Cut Diamond: An Analysis of Brilliance” by T. Scott Hemphill, Ilene M. Reinitz, Mary L. Johnson and James E. Shigley.

The cut grading system used in an AGA-CERT is based on a stricter standard than that in use at the time by AGS. The NAJA adopted the cut standard used in the AGA-CERT. The developers at Moscow State University, creators of DiamCalc — cut gemstone modeling software program — also adopted the AGA Cut Class system for fancy shapes. DiamCalc is widely accepted and used around the world today. If you look for the AGA Cut Class system on the internet, you’ll find it in hundreds of locations and in daily use. Tens of thousands of diamond grading reports using the system have been issued without any reported “problems” with dealers or consumers.

THE DFS SYSTEM Late 1990’s

In the late 1990s, D. Atlas became involved with ImaGem, Inc., a research organization developing technology for the gem and jewelry industry. One of the areas of research that ImaGem focused on was direct measurement of light return from a diamond. This development is significant in that previously the quality of cut of a diamond was used as a proxy for light behavior of a cut diamond. With direct measurement of light behavior a commercial reality, the parametric cut grade could be used to reveal the additional value of a diamond. But although direct measurement of light behavior is a significant advancement in assessing the appearance of a stone, it doesn’t measure, for example, the craftsmanship and durability that went into making a stone. Keeping this in mind, the AGA Cut Class has been simplified to DFS-Cut grading system. Fewer parameters need to be measured to use the DFS-Cut grading system, thanks to new technology that can directly assess the appearance of a diamond. DFS-Cut grading system takes into account the properties of diamond material and the craftsmanship that goes into the cutting of each individual diamond.

DFS-Cut grading system scores the cut grade of a diamond on a 0 to 4 scale; 0 represents the highest grade and 2 is the midpoint on the scale. To make sure the contributions of various parameters toward the calculated value are properly taken into account, DFS-Cut grading scale is constructed by weighting the parametric values. The weighting scheme has to be internally consistent while representing the quality of craftsmanship. Dr. Lalit Aggarwal of ImaGem, Inc. assisted in converting the basic concepts into a formula that would create results that learned experts will find to be useful.

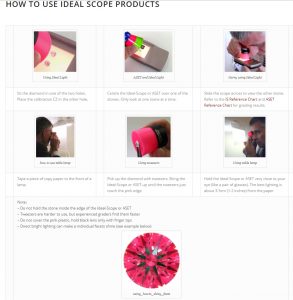

DFS-Cut Grade software, developed jointly with ImaGem, Inc., allows the cut grade of a diamond to be calculated in a customer’s own facility. It is a perfect addition to direct measurement of light behavior in order to give a complete picture of the quality, craftsmanship and appearance of a diamond. DFS-Cut Grade results can be generated with an ImaGem GL3100, a Sarin, an Ogi or a Helium device. DFS-Cut Grade software can be used with hand measuring tools, an optical retical or an old GIA-AGS Proportion scope. The more accurate and repeatable a measuring device, the more reliable will be the cut grade results from using the DFS-Cut Grade software. Direct measurement of light behavior and DFS-Cut Grade are both crucial to the increasingly asked consumer question, “How well is my diamond cut?”

D. Atlas’ own opinion is that it would be better to independently report the cut grades from the DFS-Cut Grade system and ImaGem’s direct measurement of light behavior, although some may choose to combine the two. For example, a stone may not score highly on craftsmanship and yet display very attractive light behavior. Several examples of old mine cut stones have scored low on the DFS-Cut Grade system but scored highly on ImaGem’s direct measurement of light behavior. Well-crafted, modern cut diamonds do not always perform in an equal manner. Grading craftsmanship separately from light behavior gives a clear description of the unique properties and value of each individual diamond.

USING THE DFS SYSTEM

To use the DFS-Cut Grade system, it is necessary to have total depth percentage, minimum and maximum girdle thickness grades, culet grade, polish grade and symmetry grade for round and fancy cuts. For round cuts, average crown angle is also necessary. Each diamond is given a score of 0, 1, 2, 3, or 4 on the DFS-Cut Grade scale. An explanation of the DFS-Cut Grade score and its qualitative representation are given below. To use the DFS–Cut Grade software, enter the shape, total depth percentage, minimum and maximum girdle thickness grade, culet grade, polish grade, symmetry grade and for rounds, enter the crown angle, in appropriately marked fields. The software will immediately give a DFS-Cut Grade. It is that easy. The use of the DFS-Cut Grade system with ImaGem’s direct measurement of light behavior can provide a complete assessment of the quality and value of a stone. DFS-Cut Grade system doesn’t assign a monetary value to a stone. Thankfully, the free market continues to set the value.

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

Crown angle, girdle thickness, finish, total average depth percentage and culet size are the five parameters that make up DFS-Cut Grade system. Each parameter is scored individually; the score also creates a ceiling for an overall DFS-Cut Grade. For example, average crown angle for round diamonds only affects overall cut grade as follows:

Average Crown Angle for Round diamonds only:

• Average crown angle of 29 degrees or greater,

DFS score: 0 or lower.

• Average crown angle between 26 to 28.9 degrees,

DFS score: 1 or lower.

• Average crown angle less than 26 degrees,

DFS score: 2 or lower.

Diamond is a durable material, yet chipping is a

common occurrence faced by consumers. Shallow crown angles in round stones create Durability (D) issues. Round diamonds with less than a 29 degree average crown angle may, in particular, have problematic durability. In regard to fancy shapes, many vary widely in crown angle even when very well cut. Many girdle chips do occur in areas of shallow crown angle and/or where girdles are very thin.

In DFS-Cut Grade system, Girdle Thickness for round cuts and fancy shapes affects the cut grade as follows.

Girdle Thickness for Round Cuts and Fancy Shapes:

• For thin to slightly thick girdle, DFS score: 0 or lower.

• For very thin, thick or very thick girdle,

DFS score: 1 or lower.

• For extremely thin, or extremely thick girdle,

DFS score: 2 or lower.

Girdle thickness affects both the Durability (D) and Size (S) of a stone. Girdles from Extremely Thin to Very Thin have a high risk for chipping. Girdles above Slightly Thick lose some of the potential diameter or width, which can influence the size of a stone.

Finish for Round Cuts and Fancy Shapes:

Finish of a stone is based on both polish and symmetry of a stone. DFS-Cut Grade software automatically selects the lowest score between polish and symmetry and uses it for further analysis.

• For Excellent, Very Good and Good Finish,

DFS score: 0 or lower.

• For Fair Finish, DFS score: 1 or lower.

• For Poor Finish, DFS score: 2 or lower.

Polish refers to surface condition and relative smoothness, which results in reflective properties. Symmetry refers to the outline regularity of the diamond, the matching of facet shapes to one another and the relative even nature of every facet in the design of the stone.

Total depth is primarily a Size (S) factor. When a stone is overly deep, it must be smaller in diameter or width. Very thin diamonds obviously may also have a Durability problem, but rarely get lab graded as they fail to have the light return characteristics of the far more highly valuable alternative cuts. Total Depth is factored in DFS-Cut Grade system as follows.

Total Average Depth Percentage for Round cuts:

• For Total Average Depth Percentage between 55 percent to 63.0 percent, DFS score: 0 or lower.

• For Total Average Depth Percentage below 55 percent, DFS score: 1 or lower.

• For Total Average Depth Percentage between 63 percent to 70 percent, DFS score: 1 or lower.

• For Total Average Depth Percentage above 70 percent, DFS score: 2 or lower.

Total Average Depth Percentage for Fancy Shapes:

• For Total Average Depth Percentage between 50 percent to 75 percent, DFS score: 0 or lower.

• For Total Average Depth Percentage below 50 percent, DFS score: 1 and lower.

• For Total Average Depth Percentage between 75 percent to 80 percent, DFS score: 1 or lower.

• For Total Average Depth Percentage above 80 percent, DFS score: 2 or lower.

The last factor considered in DFS-Cut Grade system is Culet Size. Culet size affects Size (S) of a stone. Historically, a pointed, closed culet was considered a durability fault, but today’s styles protect the culet from damage in nearly all cases. A large culet allows a diamond to weigh more than its diameter or width would dictate. It’s like extra fat on a cut of meat, or the butcher’s thumb on the scale. Culet Size is factored in DFS-Cut Grade system as follows.

Culet Size for Round Cuts and Fancy Shapes:

• For Culet Size between None to Medium,

DFS score: 0 or lower.

• For Large, or Very Large Culet Size,

DFS score: 1 or lower.

• For Extremely Large Culet Size,

DFS score: 2 or lower.

Scores on the above five factors are combined using

a proprietary weighting scheme to assure internal

consistency for the final DFS-Cut Grade. The meaning of the DFS-Cut Grades is as follows.

DFS-Cut Grade of 0 represents Excellent cut grade.

DFS-Cut Grade of 1 represents Very Good cut grade.

DFS-Cut Grade of 2 represents Good cut grade.

DFS-Cut Grade of 3 represents Fair cut grade.

DFS-Cut Grade of 4 represents Poor cut grade.

.